Reinventing Dimensioning: QBOID’s Mobile-First Approach

QBOID builds mobile dimensioning systems that let warehouse associates capture parcel, crate and pallet dimensions quickly using a handheld Android platform. The M2 Perceptor is designed to replace slow, manual measuring and bulky fixed-cubing stations with a small, field-ready device that includes multi-sensor 3D capture and integrated barcode scanning to feed WMS/TMS systems.

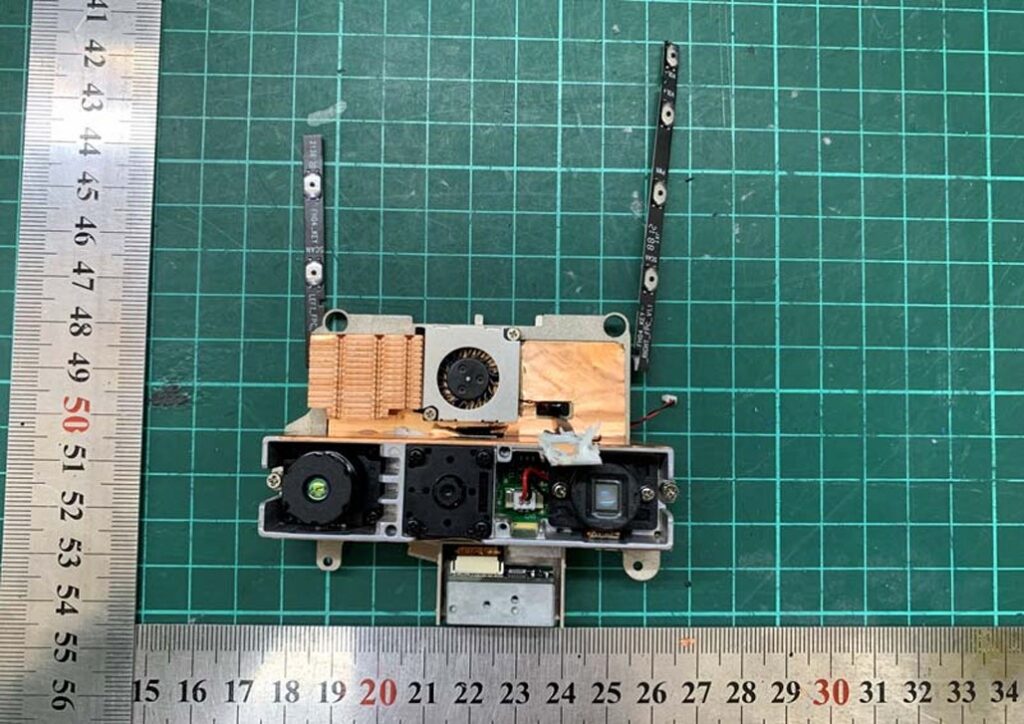

QBOID’s M2 Perceptor is a purpose-built handheld mobile dimensioner that combines multiple 3D sensors, RGB imaging and barcode scanning to deliver instant L×W×H and shape measurements across parcels, irregular items and pallets. By integrating Orbbec’s Astra Mini Pro module into the M2, QBOID achieved a compact, power-efficient sensor stack that increases depth fidelity across the device’s usable range — enabling faster throughput, more reliable irregular-item sizing and seamless integration into warehouse workflows.

The Warehouse Bottleneck: Fast, Accurate Measurements at Scale

Logistics operations need mobile dimensioning that meets three practical requirements:

- Accurate depth across ranges. A single handheld unit must reliably measure small boxes at close range and full pallets at several meters without swapping sensors.

- Dense, repeatable point clouds for irregular shapes. Boxes are easy; irregular items and mixed pallets need higher depth fidelity for correct hull/shape estimation.

- Embedded, manufacturable hardware. The sensor must be compact, low power and supported by developer tools so the M2 firmware and apps can be developed and scaled quickly.

QBOID selected sensors and components with those constraints in mind when designing the M2 Perceptor.

Why Orbbec Astra Mini Pro

The Astra Mini Pro is a bare-module structured-light 3D camera designed for embedded integration. It provides high-quality depth processing with a single USB 2.0 connection, a developer-friendly SDK, and the range and resolution needed for mixed parcel/pallet workflows. Key product attributes used by QBOID: field of view and depth processing optimized for indoor logistics, depth output suitable across ~0.6–5 m, and up to 640×480 depth frames at 30 fps — all in a compact, embeddable form factor. These specs matched QBOID’s need for a modular, repeatable sensor that could be mounted inside a handheld housing and used reliably across warehouse lighting conditions.

Seamless Integration: From Sensor Module to Handheld Breakthrough

Orbbec and QBOID engineers worked together on a pragmatic integration path that prioritized robustness and manufacturability:

- Mechanical integration: Astra Mini Pro modules were mounted within the M2 housing using custom brackets and shielding to preserve the field of view while protecting the bare module in daily warehouse use.

- Power & connectivity: The Astra Mini Pro’s single-cable USB 2.0 power + data design simplified wiring in the handheld housing while keeping thermal and power budgets manageable for a mobile device.

- Calibration & fusion: Intrinsic and extrinsic calibration aligned depth and RGB frames. Where QBOID uses more than one depth module, multi-view fusion reduces occlusion and extends effective range for pallet capture.

- Software: Orbbec’s SDK provided immediate access to depth frames and point clouds for QBOID’s dimensioning pipeline. QBOID’s algorithms perform real-time shape detection, L×W×H estimation and irregular-item hull extraction—delivering dimension results to the M2 UI and to backend systems in sub-second workflows.

Results & business impact

After integrating the Astra Mini Pro into the M2 Perceptor, QBOID reported measurable operational benefits:

- Faster, more consistent capture: The M2 delivers instant dimensioning for single parcels and reliable measurements on irregular items and pallets, reducing manual measuring time and rework.

- Reduced equipment footprint: Handheld devices with Orbbec modules enable many capture scenarios previously requiring fixed stations, reducing capital and floorspace needs.

- Easier scale-up: The bare-module design and Orbbec SDK simplified replication across production units and sped the software integration cycle for QBOID’s team.

These outcomes translate directly to lower labor cost per item, cleaner WMS data for cartonization and shipping decisions, and faster onboarding for inventory capture programs.

“Integrating Orbbec’s Astra Mini Pro into the M2 Perceptor gave us the depth quality and integration flexibility we needed to deliver fast, repeatable measurements across parcels and pallets — all in a handheld form factor. That reliability directly reduces cycle time and improves downstream packing accuracy.”

— Bin An, QBOID, CEO