Production lines are becoming increasingly complex, raising the demand for more accurate, reliable inspection systems. While 2D imaging only measures contrast and edges in a flat plane not object size or distance, 3D vision measures real-world geometry and surface topology. These systems are redefining automated inspection capabilities, making them transformative across numerous industries.

This article examines how 3D vision systems are used in automated manufacturing for quality control, the key technologies powering these systems, and how to integrate them into production lines.

How 3D Vision Powers Automated Inspection Systems

3D vision is one of the key technologies behind modern automated quality control systems. It captures depth information to reconstruct objects’ shapes, sizes, and positions. While traditional 2D inspection systems only infer the thickness or height of objects from shadows, 3D vision system measures real depth and maps every feature, such as volume and tiny surface anomalies, with high precision.

3D systems combine advanced imaging technologies, sophisticated algorithms, and, most often, artificial intelligence and machine learning. 3D vision systems yield reliable measurements even when color and contrast vary or when measuring reflective or textural parts. For instance, they can verify internal cavities and threads and even quantify warpage and shrinkage.

This shift to 3D vision systems has turned inspections from pass-or-fail checks into comprehensive geometric analyses. Manufacturers can accept, rework, or reject work based on the true dimensional compliance — not proxies. They can also tune machines faster by correlating deviations with upstream parameters, reducing scrap and improving first-pass yield.

Core 3D Vision Technologies for Quality Control

These core 3D vision technologies cover the full spectrum of manufacturing needs, from fast, robust inline checks to precision metrology. Teams can select the best fit for their applications in terms of accuracy, speed, field of view, and environmental constraints.

Time-of-Flight (ToF) Cameras

ToF cameras compute pixel depth by emitting modulated or pulsed light and measuring the time it takes to return from the surface. Modern ToF sensors can deliver dense point clouds at high frame rates with low latency.

ToF works best with high-throughput lines, large fields of view, and moving targets. It is excellent for:

- Inline height mapping.

- Measuring volumes like food portioning or fill-level verification.

- Inspecting pallets or packaging.

ToF tolerates ambient variation better than purely passive methods and is suited for multi-camera synchronization over wide areas. Orbbec’s ToF cameras can provide high-speed, inline measurements and volume checks. They perform exceptionally well in variable lighting conditions.

Structured Light Scanners

Structured light scanners use a projector to cast a known pattern, like stripes or dots, onto an object. One or more cameras observe the pattern’s deformation and use triangulation to reconstruct the 3D surface at high resolution.

These scanners are effective for metrology-grade inspections of static or indexed parts. Structured light can capture finer details such as small edges, surface waviness, or micro-scratches. It is often used for:

- First-article inspection.

- Verifying geometric dimensioning and tolerancing (GD&T) against CAD.

- Detailed defect detection where micrometer-level precision is needed.

Orbbec’s structured light cameras, like the Astra Series, offer high-resolution for metrology-oriented surface inspections and GD&T checks.

Active and Passive Stereo Vision

Active and passive stereo vision involve two or more cameras viewing a scene from different angles. The system triangulates depth by matching features between images, a lot like human vision. Active stereo provides a projected pattern to improve texture on low-contrast surfaces, while passive relies on natural texture.

These systems allow flexible setups for robot guidance, bin picking, assembly verification, and mixed-part handling. Active stereo vision is remarkable for challenging, low-texture parts and does well in variable lighting. Passive stereo does best in well-lit environments with textured surfaces, offering cost-effective depth without a projector.

Orbbec’s stereo vision cameras provide versatile, depth-rich inspection and robot guidance.

Key Applications in Manufacturing Inspection

3D machine vision systems are used in many industries, from manufacturing and automotive to aerospace and electronics. Key applications include the following.

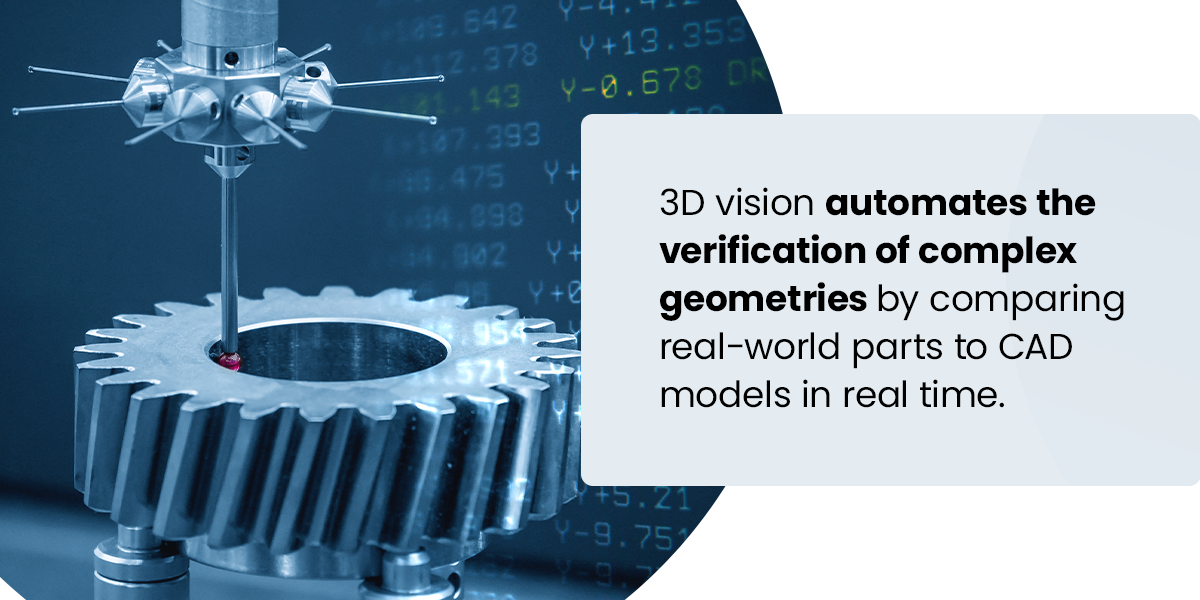

GD&T

3D vision automates the verification of complex geometries. It can measure flatness, parallelism, true position, profile, runout, and more. By comparing captured point clouds to CAD, systems can compute the deviations in real time, generating a pass-fail decision with statistical evidence.

This process replaces slow, manual tools like calipers or single-point gauges. It also reduces reliance on coordinate measuring machines for routine checks, freeing them up for critical audits.

Surface Finish and Defect Analysis

Automated vision inspection equipment can detect subtle defects earlier on, reducing warranty risk or the need for rework. High-resolution depth maps reveal defects such as:

- Scratches

- Pits

- Porosity

- Burrs

- Warpage

- Sink marks

- Coating thickness variation

All are issues that a 2D image or the naked eye could miss. When it comes to consumer goods and packaging, 3D inspection can handle portion control and packaging verification. For example, these systems can measure fill levels, seal integrity, cap alignment, and label planarity.

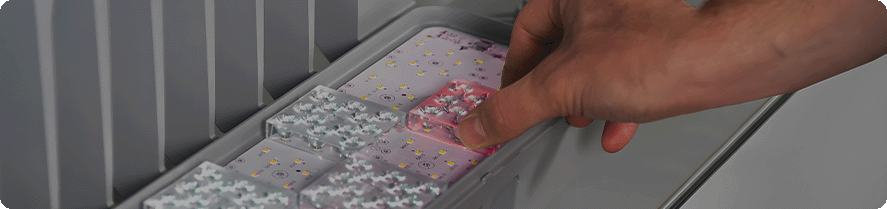

Assembly and Component Verification

Automated visual inspection systems use 3D data to confirm:

- Component presence.

- Orientation.

- Insertion depth.

- Seating.

They can detect cross-threaded fasteners, missing pins, or misaligned connectors before the final pack-out. With depth-aware checks, robots can adapt their paths to avoid collisions, improving effectiveness and preventing failures down the line.

Integrating 3D Vision Into Production Lines

Manufacturing teams must consider the following factors when integrating 3D vision into their production lines:

Data Processing and Software Integration

3D cameras generate large datasets, from point clouds to meshes and height maps. This data needs efficient processing software for filtering, segmentation, feature extraction, and CAD-to-cloud comparison at line speed.

Software development kits (SDKs) and application programming interfaces are essential for integration. They help connect the vision stack to programmable logic controllers and robots for control.

Environmental and Lighting Factors

Ambient light, part reflectivity, and motion influence the quality of the data gathered by 3D vision systems. ToF does best in a controlled infrared environment, for example, while active stereo and structured light need proper pattern contrast and exposure management. Strategies can include shrouding, optical filters, polarizers, and anti-reflective fixturing.

Consistent part presentation is also essential. 3D vision systems require stable fixturing, vibration control, and known orientation to improve repeatability and reduce the algorithms’ complexity.

Calibration and System Accuracy

Calibration is crucial for metrology-grade results. Intrinsic calibration ensures each camera’s internal model is accurate, while extrinsic calibration locks the 3D system to robots, fixtures, or conveyors. With scale verification, teams can tie measurements to traceable standards. To maintain accuracy and repeatability, teams should regularly check gauge blocks or artifacts and monitor statistical process control, especially critical for regulated industries.

Build Your Automated Quality Control System With Orbbec

The camera is the foundation of any high-performance automated quality control system. Orbbec offers proven building blocks for OEMs and integrators to tailor solutions to their exact accuracy, speed, and environmental requirements. From depth cameras to SDKs, reference designs, and accessories, Orbbec shortens time-to-value with end-to-end, production-ready components.

Combine Orbbec depth with robust SDKs and industrial interfaces to accelerate development and scale confidently from pilot to full production. Contact us to consult about products or OEM services today.