Today’s fast-paced supply chain has facilities looking for new ways to improve efficiency and stand out from the competition. Simultaneous Localization and Mapping (SLAM) robotics is making warehouses more efficient, flexible, and scalable. SLAM powers Automated Guided Vehicles (AGVs) to move through environments without a track, avoid obstacles, and respond to changes much faster than traditional solutions.

These robots can automate numerous warehouse tasks, making them invaluable to modern warehouses looking to future-proof their operations. To successfully integrate SLAM robotics, warehouse managers will need to understand the technology and algorithms behind their automation and determine their operational goals.

What Is SLAM Robotics?

SLAM lets robots map spaces and position themselves in a setting in real time. In warehouses, SLAM allows Autonomous Mobile Robots (AMRs) to move through spaces without getting stuck on obstacles or unforeseen challenges, helping with tasks like item picking and handling.

SLAM-powered robots can take different approaches to map out their surroundings and navigate a warehouse:

- Visual SLAM (vSLAM): This approach involves using cameras to create rich, detailed maps so AMRs can determine their position in an environment.

- LiDAR-based SLAM: This approach uses laser sensors to precisely measure distance points. It is often used in large, open spaces that have limited lighting.

- Hybrid SLAM: Hybrid SLAM combines vSLAM and LiDAR SLAM. The approach uses visual and laser data to better determine the robot’s position in the warehouse and move even more efficiently.

How Is SLAM Robotics Used for Warehouse Automation?

SLAM robotics can automate warehouse tasks like material transport, inventory movement, and order picking — all without human’s help. Unlike traditional AGVs, these robots don’t need fixed tracks or markers to get around a warehouse. They adapt to changes quickly, accounting for obstacles or workflows that might get in their way.

The system uses sensors, like cameras for vSLAM and LiDAR, to continually map the robot’s surroundings and position it within a space. This allows the robot to move quickly and plan routes with ease. The mapping feature can also be integrated with warehouse management systems.

SLAM robotics can help warehouses increase their throughput, avoid errors associated with human work, and respond quickly to changing demands. Robots can complete tasks much faster than human employees, allowing personnel to take care of other higher-value tasks.

3D Vision Integration: Cameras and Sensor Technology in SLAM Robotics

3D vision allows robots to understand depth, recognize objects, and move through spaces. Advanced cameras make it easy for AMRs to create accurate maps and avoid obstacles in real time — even in warehouses with spaces that are constantly changing.

Modern AMR cameras use stereo vision and time-of-flight (ToF) cameras. Orbbec has extensive experience with 3D vision systems, developing cameras with high frame rates, wide field of views, and superior performance in different lighting conditions. Warehouse managers can even opt for vision systems that combine ToF and stereo vision for a high-performance solution.

Stereo Vision

The stereo vision technique uses two cameras to capture two images of the same scene. It calculates the distance between matching points in the images to determine the depths of objects. Orbbec’s Gemini series includes stereo vision cameras that can:

- Support cobots: These cameras give cobots their highly precise perception capabilities, enabling them to carry out assembly, inspection, and handling tasks safely and efficiently.

- Support shelf-stacking: These cameras give 3D spatial data to recognize shelves, locate products, and plan paths. They can help with automated picking, inventory management, and goods sorting.

Time of Flight (ToF)

This technology measures the time it takes for light to travel from the camera to an object and return. ToF cameras can determine distance and process data in real time, making them an effective solution for complex warehouse layouts. For example, Orbbec’s Femto series includes a ToF camera that can help with tasks like:

- Order picking: This camera captures spatial information about objects on a pallet for precise picking.

- Loading and unloading: The camera can accurately measure distances for more precise robot handling.

- Large object dimensioning: The camera automatically determines the dimensions of large objects on a moving production line, helping warehouses calculate costs and sort oversized objects.

Camera Integration Best Practices

To integrate 3D cameras with the SLAM system, warehouses will need to:

- Position the cameras for optimal field of view: Cameras must be strategically positioned on the AMRs for the best field of view, minimizing blind spots. Facilities should keep in mind the typical obstacles of a given workday and the warehouse’s layout when positioning them.

- Calibrate sensors correctly: Cameras and sensors must be calibrated to ensure precise depth perception and alignment with the robot’s coordinate system.

- Ensure the AMR software is compatible: Warehouses need to make sure their AMR software is fully compatible with the chosen camera hardware and SLAM algorithms.

Orbbec provides comprehensive support and can make sure the system performs reliably for even the most demanding applications.

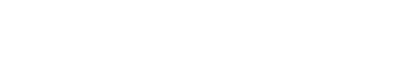

Key SLAM Algorithms and Their Warehouse Applications

SLAM algorithms allow robots to map their environment and know their location simultaneously. They can be divided into three main categories.

Filter-Based SLAM

Filter-based algorithms help a robot figure out its current position and the layout of the warehouse at any given moment, using all the information the robot has collected so far. The robot is constantly updating its “best guess” of where it is and what the environment looks like as it moves and gathers new data. The Kalman filter, for example, is a type of filter-based SLAM algorithm, where the robot guesses where it is by making a prediction. Then, the filter corrects that guess with sensor data.

Filter-based SLAM often works best in structured environments with predictable movements.

Graph-Based SLAM

In a graph-based SLAM algorithm, the robot creates a graph of all the places it has been, or poses, and the connections between them. Poses are represented as points on a graph, while the edges represent how the robot moved or what it learned from the environment. As the robot explores its space, it adds new points to the graph that represent each position or landmark.

The goal is to adjust the entire graph so that all positions and landmarks fit together as accurately as possible with minimal errors in the map or understanding of its location. Special algorithms like Square Root SAM can help speed up this process. Graph-based SLAM is suitable for large, more visually complex spaces since it can handle changing layouts more accurately.

Deep Learning SLAM

Deep learning-based SLAM uses neural networks to help robots map and understand their surroundings. While new, this approach shows promise in helping robots process visual information more easily and make better navigation decisions.

One early example is RatSLAM, which mimics how a rat’s brain works to help a robot use visual and movement cues for navigation. RatSLAM works well in some visually rich spaces and is being refined so that it can more easily adapt to changing environments.

Benefits of SLAM Robotics in Warehouse Environments

SLAM robotics can enhance a warehouse’s safety and increase its throughput during peak periods. Here are a few of the benefits of integrating SLAM robotics into warehouses.

Improved Navigation

SLAM allows AMRs to navigate spaces more accurately than before. They can autonomously move through nondeterministic spaces, updating their paths to avoid obstacles and responding to changes as they occur. Warehouses don’t have to update their infrastructure to implement SLAM because these systems don’t rely on fixed tracks. Instead, warehouses can reconfigure their layout as their business changes and evolves.

Reduced Labor Costs and Operational Errors

SLAM robots are efficient and accurate, which translates to lower labor costs and fewer errors. They can take over the more physically demanding, repetitive tasks while human employees focus on higher-value objectives. With their precise algorithms, SLAM-powered AMRs can also minimize errors in a warehouse. They can handle inventory and pick orders with greater accuracy, helping warehouses keep track of items and maintain high customer satisfaction.

Minimized Downtime Risk

Downtime is a major concern for warehouses. SLAM robotics helps minimize this risk since these AMRs work around the clock. They can ensure high throughput even during peak periods or labor shortages by self-navigating warehouses and responding to obstacles to prevent bottlenecks and delays.

Enhanced Safety

SLAM robots can improve a warehouse’s safety by taking care of the more physically challenging tasks so human workers don’t have to. This can prevent accidents and injuries. Robots with sensors and real-time mapping can also detect and avoid humans and moving objects.

Scalability

As warehouses grow, SLAM-powered AMRs can evolve alongside their fleet. That’s because these robots don’t need to be reprogrammed — they respond and adapt to changing warehouses. This also means facilities can avoid drastic infrastructure updates and the costly downtime. All they need to do is implement SLAM once to future-proof their entire operation.

How to Implement SLAM Robotics in a Warehouse

Following a step-by-step approach can ensure a smooth transition to more advanced automation and a maximized return on investment.

1. Assessing Warehouse Needs and Readiness

Warehouse managers must consider their current workflows, layout, and operational challenges. They should identify areas that might benefit from automation, such as repetitive transport routes or locations prone to human error. Environmental factors like lighting, many obstacles, and floor conditions should also be considered when choosing the right SLAM technology.

Orbbec’s solutions are highly customizable, including options for embedded applications, allowing warehouses to tailor the 3D vision system to their unique operational needs.

2. Selecting the Right SLAM Technology

Next, warehouses will need to choose an approach that works best for their site. For example, vSLAM relies on cameras and is suitable for visually rich and well-lit spaces. LiDAR-based SLAM works well in large, open, or low-light spaces. Hybrid systems can combine the best of these for better compatibility. Consulting with experts or technology partners like Orbbec can help warehouse managers match the right solution to their facility’s needs.

3. Choosing and Integrating 3D Cameras

For vSLAM applications, choosing the right 3D cameras is crucial. Cameras must be positioned to maximize field of view and avoid blind spots, and they should be properly calibrated to get the most accurate depth perception. Orbbec offers a range of cameras designed for warehouse AMRs, with support resources to streamline integration.

Orbbec’s in-house manufacturing and supply chain management ensure reliable, scalable delivery worldwide, while their global service network supports customers wherever they operate.

4. Setting up Infrastructure and Mapping the Environment

Teams will need to prepare their warehouse and ensure they have reliable network connectivity, charging stations, and safety barriers if needed. Running SLAM-powered robots through the facility allows them to create detailed maps and identify important landmarks to determine their location and navigate efficiently.

5. Testing and Calibrating

The next step is to test the robot, piloting it in a controlled area to make sure it navigates correctly, avoids obstacles, and performs tasks to the best of its abilities. Teams can gather feedback to fine-tune their setup, recalibrate sensors, and address any issues before scaling up.

6. Implementing Safety Protocols With SLAM-Based Robotics

To make sure the robot can safely interact with human employees, warehouse teams will need to deploy robust collision avoidance systems. This way, robots can detect and respond to humans and avoid obstacles. It’s also crucial to consider regulatory requirements and stay up to date on compliance and safety regulations to protect workers.

7. Training Staff and Monitoring Performance

Warehouse personnel should be trained on how to operate and service SLAM robots, including how to troubleshoot common issues and interpret system data. By keeping track of any issues and monitoring performance, warehouses can find ways to improve their SLAM system and ensure long-term success.

8. Expanding From Pilot to Full-Scale Deployment

To get the most from a SLAM solution, warehouse teams should start with a small-scale pilot and then expand as they gain confidence using the robots. This way, they can refine their processes and realize the full potential of their automation investment.

Start Your Warehouse Automation Project With Orbbec

Implementing SLAM robotics in warehouses can be challenging without the right expertise and technology partner. Orbbec simplifies this process, offering advanced 3D cameras, robust SDKs, and seamless integration with AMRs, all proven by successful deployments in leading warehouses. Since 2013, Orbbec has built a global reputation as a pioneer in 3D vision, delivering high-performance 3D vision sensors and tailored robotics solutions for warehouses, robotics, 3D scanning, and more.

Orbbec’s global management team brings deep expertise in robotics, AI, and vision systems, so you benefit from world-class leadership and support. Orbbec is proud to support a vibrant developer community, providing resources and tools that empower engineers and innovators to build the next generation of intelligent machines.

With Orbbec automation solutions, warehouses can improve navigation, reduce downtime, and ensure greater operational flexibility. Ready to transform your warehouse? Contact Orbbec today to learn about the available automation solutions and discuss your project with an expert team.